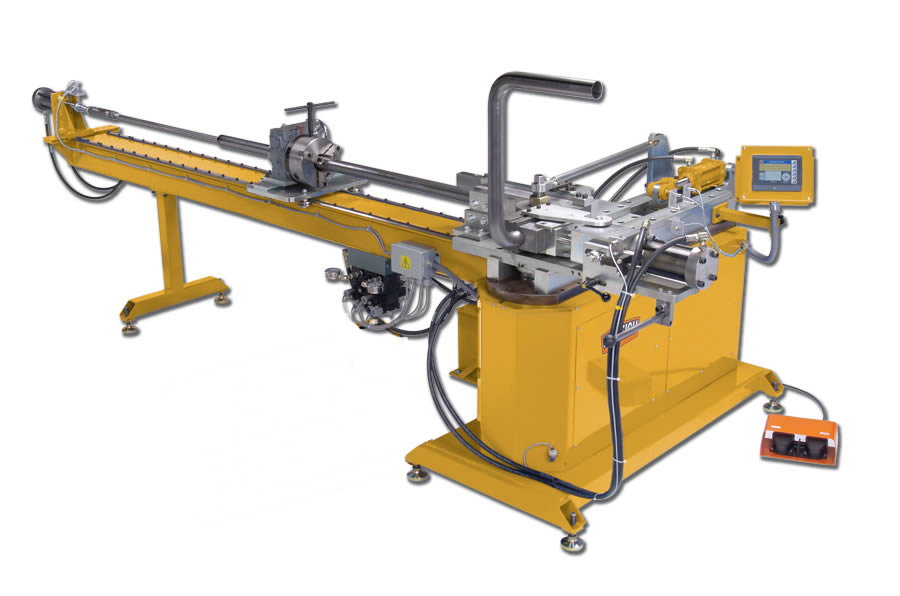

Great for tight radius bends (down to 1-1/2 times the OD).

- User friendly operation

- Perfect for small to mid-sized productions

- Quick changeovers and cycle times

- Touch screen controls; able to input 140 programs with 10 bends per program

Key features:

- 10 foot extraction table

- Rotary positioning carriage with 4 manual stops

- Set up of tooling consists of: rotary bending die, clamp die, pressure die, mandrel, wiper die (additional tooling available depending on bending requirements)

- Right handed mandrel pipe bender

- Single stack tooling

- Electrical mechanical drive system for bend axis

- Clamp die has hydraulic and mechanical locking system that reduces the possibility of slippage

- Mandrel extractor uses powerful hydraulic system to insert, hold, and extract the mandrel

- Follower die is positioned and held tight against rotary die and wiper die

- Foot pedal control works in conjunction with touch screen instructions

Max Bending Strength Capacity:

- Round Mild Steel – 3″OD x .125″ Wall

- Round Aluminum – 3″OD x .188″ Wall

- Round Stainless – 3″OD x .065″ Wall

- Square Mild Steel – 2″x2″ x .188″ Wall

- Solid Bar Mild Steel – 1.181″OD

Specifications

- Max bend radius – 9” CLR

- Max bend angle – 190 degrees

- Max length over mandrel – 10”

- Bending speed (DOB) – 18 degrees per second

- Accuracy of DOB - +/- 0.50°

- Machine Weight - 2100 lb

- 220V x 60Hz x 3 Phase

REQUEST A QUOTE FOR THIS MACHINE

Fill out the form and send it through to our team and we can help you get started with your inquiry.